Views: 0 Author: Site Editor Publish Time: 2025-09-28 Origin: Site

In the realm of mineral processing, the shaking table stands as a pivotal tool for the separation and concentration of mineral particles. Its significance is underscored by its ability to efficiently separate minerals based on their specific gravity differences. This article delves into the multifaceted applications of shaking tables in mineral processing, exploring their mechanisms, advantages, and the science behind their operation. For those interested in the technical specifications and applications of shaking tables, the shaking table provides a comprehensive overview.

Shaking tables operate on a simple yet effective principle: the stratification of mineral particles based on their specific gravity. The table itself is a slightly inclined surface, oscillating back and forth, which causes the denser particles to migrate to the bottom, while lighter particles remain on top. This separation process is enhanced by the addition of water, which aids in the movement and stratification of particles. The combination of gravity and water flow allows for the efficient separation of minerals, making shaking tables an indispensable tool in mineral processing.

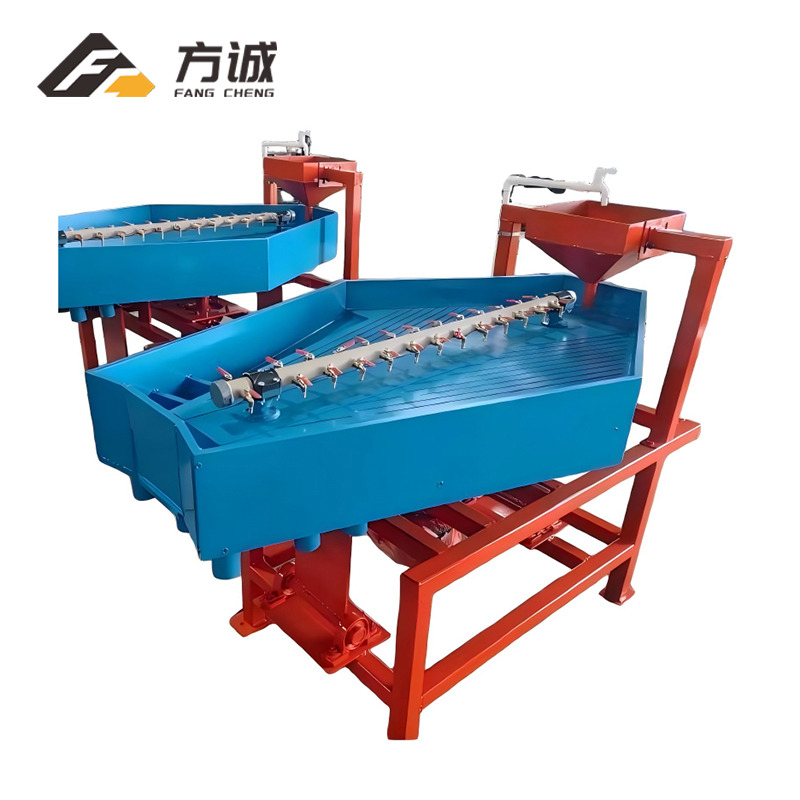

The design of a shaking table is crucial to its function. Typically, it consists of a rectangular deck, supported by a frame, and equipped with riffles to aid in the separation process. The deck is usually made of a durable material, capable of withstanding the rigors of mineral processing. The riffles, or raised strips, are strategically placed to enhance the separation of particles by creating turbulence in the water flow. This turbulence helps to stratify the particles, allowing for more precise separation.

The operation of a shaking table requires careful calibration to achieve optimal results. Factors such as the angle of inclination, the speed of oscillation, and the water flow rate must be precisely controlled to ensure efficient separation. The efficiency of a shaking table is measured by its ability to produce a high-grade concentrate with minimal loss of valuable minerals. Studies have shown that shaking tables can achieve recovery rates of up to 95% for certain minerals, making them a highly effective tool in mineral processing.

Shaking tables are used extensively in the mining industry for the concentration of precious metals such as gold, silver, and platinum. Their ability to separate fine particles makes them particularly useful in the recovery of these metals from ore. In addition to precious metals, shaking tables are also used for the concentration of other minerals, including tin, tungsten, and chromite. Their versatility and efficiency make them a valuable asset in any mineral processing operation.

One of the most common applications of shaking tables is in the recovery of gold. Gold particles, due to their high specific gravity, are easily separated from lighter gangue materials using a shaking table. The process involves feeding a slurry of crushed ore and water onto the table, where the gold particles are concentrated and collected. This method is particularly effective for the recovery of fine gold particles, which are often lost in other separation processes.

Beyond gold recovery, shaking tables are also used for the concentration of other minerals. For example, they are used in the separation of tin from its ore, as well as the concentration of tungsten and chromite. The ability to separate minerals based on specific gravity makes shaking tables a versatile tool in mineral processing, capable of handling a wide range of materials.

While shaking tables offer numerous advantages in mineral processing. Understanding these is crucial for optimizing their use in various applications.

The primary advantage of shaking tables is their ability to produce high-grade concentrates with minimal loss of valuable minerals. They are also relatively simple to operate and maintain, making them a cost-effective option for mineral processing. Additionally, shaking tables are capable of handling a wide range of particle sizes, from fine to coarse, making them versatile tools in mineral processing operations.

In conclusion, the shaking table is a valuable tool in mineral processing, offering numerous advantages in the separation and concentration of minerals. Its ability to produce high-grade concentrates with minimal loss of valuable minerals makes it an indispensable tool in the mining industry. However, it is important to understand its limitations and optimize its use for specific applications. For more information on the technical specifications and applications of shaking tables, the shaking table provides a comprehensive overview.

1. What is the primary function of a shaking table in mineral processing?

The primary function of a shaking table is to separate and concentrate mineral particles based on their specific gravity differences.

2. How does a shaking table operate?

A shaking table operates by oscillating back and forth, causing denser particles to migrate to the bottom while lighter particles remain on top, aided by water flow.

3. What minerals can be concentrated using a shaking table?

Shaking tables are used for the concentration of precious metals like gold, silver, and platinum, as well as other minerals such as tin, tungsten, and chromite.

4. What are the advantages of using a shaking table?

Shaking tables offer high-grade concentrates with minimal mineral loss, are simple to operate and maintain, and can handle a wide range of particle sizes.

5. What are the limitations of shaking tables?

Limitations include reduced effectiveness for very fine particles, limited capacity for large-scale operations, and efficiency affected by particle shape and density.

6. How is gold recovered using a shaking table?

Gold recovery involves feeding a slurry of crushed ore and water onto the table, where gold particles are concentrated and collected due to their high specific gravity.

7. Where can I find more information on shaking tables?

For more detailed information on shaking tables, including technical specifications and applications, visit the shaking table resource.