PRODUCT INTRODUCTION

Gravity separation offers an efficient, chemical-free method for mineral concentration by using natural density differences. Our equipment achieves high recovery for gold, tungsten, tin, tantalum-niobium, chromite, ilmenite, zircon, rutile, monazite, barite, coal, and other metal and non-metal minerals. It features simple operation, low energy use, and stable performance across various processing conditions.

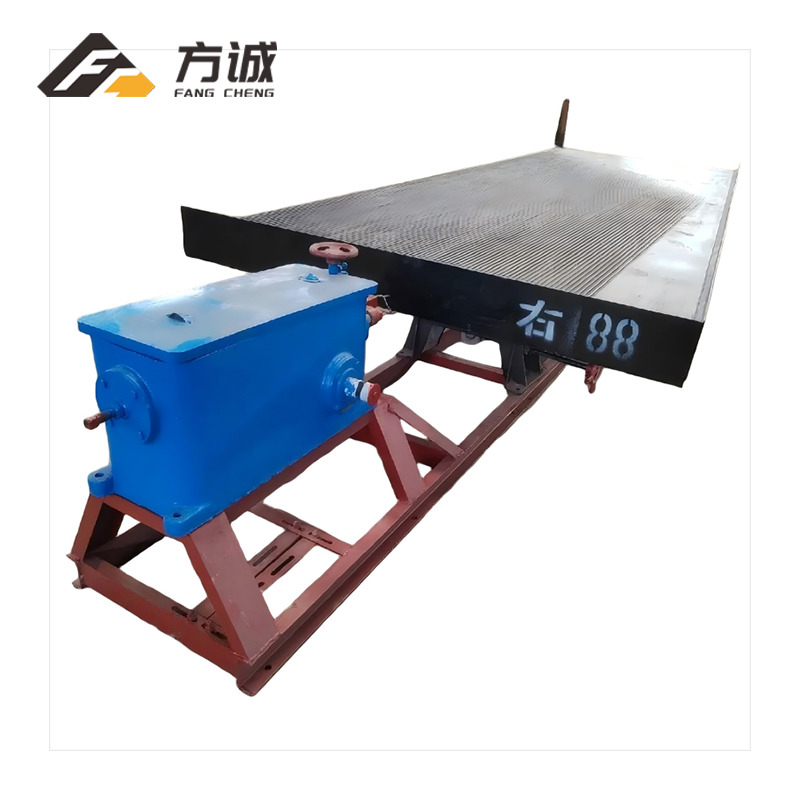

With advanced designs including spiral chutes, shaking tables, jig machines, and high G-force concentrators, Fangcheng’s gravity separators produce cleaner concentrates while reducing tailings loss. Built with wear-resistant materials and engineered for tough mining environments, each unit ensures reliable operation, long service life, and cost-effective beneficiation for both coarse and fine minerals.

PRODUCT ADVANTAGES

Chemical-Free, High-Recovery Separation

Our gravity separators rely on natural density differences, enabling high recovery without chemical reagents. This ensures safer operation, lower environmental impact, and stable performance across a wide variety of metallic and non-metallic minerals.

Low Energy Use and Easy Operation

Designed for efficiency, the equipment requires minimal power while maintaining strong separation results. Simple controls and user-friendly operation reduce labor intensity and ensure consistent performance in daily beneficiation tasks.

Advanced Designs for Cleaner Concentrates

Using optimized spiral chutes, shaking tables, and high G-force systems, our equipment delivers cleaner concentrates with reduced tailings losses. This enhances processing efficiency and maximizes yield in both fine and coarse mineral applications.

Durable Construction for Harsh Conditions

Built with wear-resistant materials and reinforced structures, the equipment operates reliably in demanding mining environments. Long service life and low maintenance requirements help reduce downtime and overall operating costs.

APPLICATION

Fangcheng gravity separators, including the ABS Spiral Chute, Shaking Table, Jig Machine, Centrifugal Concentrator, etc., are designed for versatile mineral processing. They efficiently recover gold, tungsten, tin, ilmenite, zircon, and other metallic or non-metallic minerals across both fine and coarse particle sizes.

Heavy Mineral Concentration

Ideal for concentrating ilmenite, zircon, rutile, monazite, and other heavy minerals. The gravity-based process delivers high recovery, cleaner concentrates, and stable grade control for mineral sands projects, even when handling fine particle sizes and variable ore conditions.

Gold and Tungsten Recovery

Efficiently separates fine gold, tungsten, and tin ores using natural density differences. Suitable for both primary and alluvial deposits, ensuring higher recovery with low energy use and zero chemicals while maintaining excellent performance in complex, high-slurry mining environments.

Pre-Concentration and Tailings Upgrade

Used for early-stage ore pre-concentration or upgrading tailings to reduce downstream processing load. Low water demand and high separation accuracy help cut operating costs, enhance plant throughput, and improve resource utilization for more sustainable mineral processing operations.

WHY CHOOSE FANGCHENG

20 Years of Mining Experience

Professional team delivering reliable mineral processing solutions backed by long-term industry expertise.

Strong Manufacturing Strength

Modern 20,000㎡ factory ensures stable quality, fast production, and consistent global supply.

Leading Gravity Separation Technology

University-supported innovations provide high recovery, stable performance, and wide mineral applicability.

One-Stop Service Support

From mineral testing to installation and training, we offer complete project support with quick response.

RESOURCE

- Name

- Update

- Size

- Downloads

- Thumbnail

- Download

- Copy Link

- The Catalog of Fangcheng Mining Equipment Company0909.pdf

- 2025-12-02

- 3.17MB

- 10

-

- Download

- Copy Link

- Vertical Ring Magnetic Separator

- 2025-07-31

- 174KB

- 0

-

- Download

- Copy Link

- Heavy-Duty Primary Jaw Crusher for Granite & Hard Rock Crushing

- 2025-07-31

- 396KB

- 2

-

- Download

- Copy Link

- Mineral Spiral from Fangcheng.pdf

- 2025-07-28

- 8.51MB

- 12

-

- Download

- Copy Link

ABS SPIRAL CHUTE

Precision gravity separation for fine minerals, the ABS Spiral Chute efficiently recovers ilmenite, zircon, rutile, tungsten, and other ores, offering modular design, wear resistance, and eco-friendly, high-recovery performance.

Efficient Separation

Recovers fine minerals with high accuracy, using density differences for cleaner, high-grade concentrate output.

Durable Design

ABS-PU construction ensures long service life and strong wear resistance in harsh mining environments.

Easy Installation

RELATED PRODUCT

FAQs

Contact Us

Have questions or need a custom gravity separation solution? Contact Fangcheng today for expert guidance, fast response, and personalized support.

RELATED BLOGS

KEEP IN TOUCH WITH US

Stay connected with Fangcheng for the latest gravity separation solutions, product updates, and technical support. Our team is ready to answer your inquiries, provide personalized guidance, and help optimize your mineral processing projects.

Mob:+8615297826310

E-mail:info@mymeinai.com

English

English