Views: 0 Author: Site Editor Publish Time: 2025-10-14 Origin: Site

In the realm of mineral processing and recovery, the shaking table stands as a pivotal piece of equipment. Its function is not only crucial for the separation of valuable minerals from ores but also for enhancing the efficiency and effectiveness of mining operations. This article delves into the multifaceted role of the shaking table, examining its design, operational principles, and applications across various industries. For those interested in exploring the specifics of a high-precision shaking table, the shaking table offers an excellent starting point.

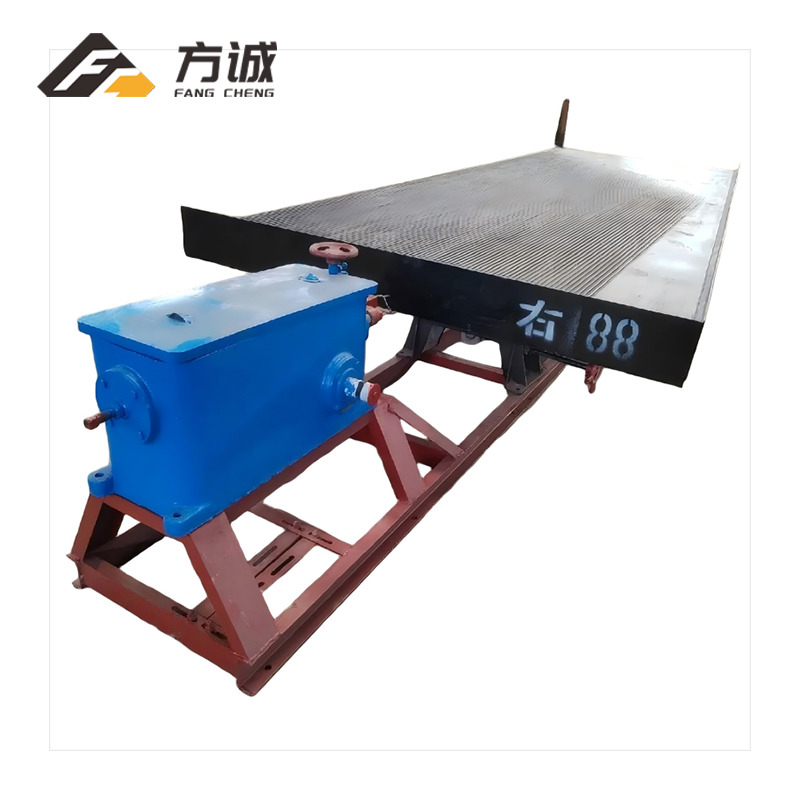

The shaking table is a device that utilizes the principles of gravity separation to sort particles based on their density. It consists of a slightly inclined deck, upon which materials are fed. The deck shakes in a back-and-forth motion, which facilitates the separation of particles. The lighter particles move to the top of the deck, while heavier particles remain closer to the bottom. This separation is achieved through a combination of gravitational forces, friction, and the table's oscillatory motion.

Typically, the deck is made of materials that enhance friction, such as rubber or linoleum, which aids in the effective separation of particles. The shaking table's efficiency is influenced by several factors, including the frequency and amplitude of the shaking motion, the deck's inclination, and the particle size distribution of the feed material. Adjusting these parameters can optimize the separation process, making the shaking table a versatile tool in mineral processing.

Shaking tables are predominantly used in the mining industry for the separation of precious metals such as gold, silver, and platinum. They are particularly effective in processing fine-grained ores, where other separation methods may fall short. The shaking table's ability to produce high-grade concentrates makes it an invaluable asset in the recovery of these metals.

Beyond precious metals, shaking tables are also employed in the processing of base metals like copper, lead, and zinc. Their application extends to the recovery of rare earth elements, which are critical in the manufacturing of high-tech devices. The versatility of the shaking table allows it to be adapted for use in various mineral processing scenarios, enhancing the overall efficiency of mining operations.

The efficiency of a shaking table is not solely dependent on its design and operational parameters. The integration of modern technologies has significantly enhanced the performance of these tables. For instance, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) has allowed for the precise engineering of shaking tables, optimizing their performance.

Moreover, advancements in materials science have led to the development of more durable and wear-resistant materials for the construction of shaking tables. These innovations have extended the lifespan of the equipment, reducing maintenance costs and downtime. As a result, the overall efficiency of mineral processing operations has improved, leading to increased profitability for mining companies.

Several case studies highlight the effectiveness of shaking tables in real-world applications. In one instance, a gold mining operation in South Africa utilized shaking tables to recover gold from tailings, achieving a recovery rate of over 90%. This success was attributed to the precise control of the table's operational parameters, which allowed for the efficient separation of gold particles from the surrounding material.

In another example, a copper mine in Chile implemented shaking tables to process fine-grained copper ores. The tables were instrumental in producing high-grade copper concentrates, which were then further refined to produce pure copper. The use of shaking tables in this context not only improved the quality of the final product but also reduced the environmental impact of the mining operation by minimizing waste.

Despite their advantages, shaking tables are not without challenges. One of the primary limitations is their relatively low throughput compared to other separation methods. This can be a significant drawback in large-scale mining operations where high volumes of material need to be processed quickly.

To address this issue, researchers are exploring ways to scale up the design of shaking tables, increasing their capacity without compromising their efficiency. Additionally, there is ongoing research into the development of hybrid systems that combine shaking tables with other separation technologies, such as flotation and magnetic separation. These innovations hold the potential to revolutionize the field of mineral processing, making it more efficient and sustainable.

The shaking table is a critical component in the field of mineral processing, offering a reliable and efficient method for the separation of valuable minerals. Its design and operational principles make it a versatile tool, capable of handling a wide range of materials. While challenges remain, ongoing research and technological advancements promise to enhance the performance and capacity of shaking tables, ensuring their continued relevance in the mining industry. For those seeking to explore the capabilities of a high-precision shaking table, the shaking table offers a comprehensive solution.

1. What is the primary function of a shaking table?

The primary function of a shaking table is to separate particles based on their density using gravity separation techniques.

2. How does a shaking table enhance mineral processing efficiency?

By optimizing operational parameters such as frequency and amplitude, a shaking table can effectively separate valuable minerals, enhancing overall processing efficiency.

3. What industries benefit from the use of shaking tables?

Shaking tables are widely used in the mining industry for the recovery of precious and base metals, as well as in the processing of rare earth elements.

4. What are the limitations of shaking tables?

One of the main limitations is their relatively low throughput, which can be a drawback in large-scale operations.

5. How are modern technologies improving shaking tables?

Advancements in CAD, CAM, and materials science have led to more precise and durable shaking tables, enhancing their performance and lifespan.

6. Can shaking tables be used in conjunction with other separation methods?

Yes, researchers are exploring hybrid systems that combine shaking tables with other technologies like flotation and magnetic separation.