Views: 0 Author: Site Editor Publish Time: 2025-10-08 Origin: Site

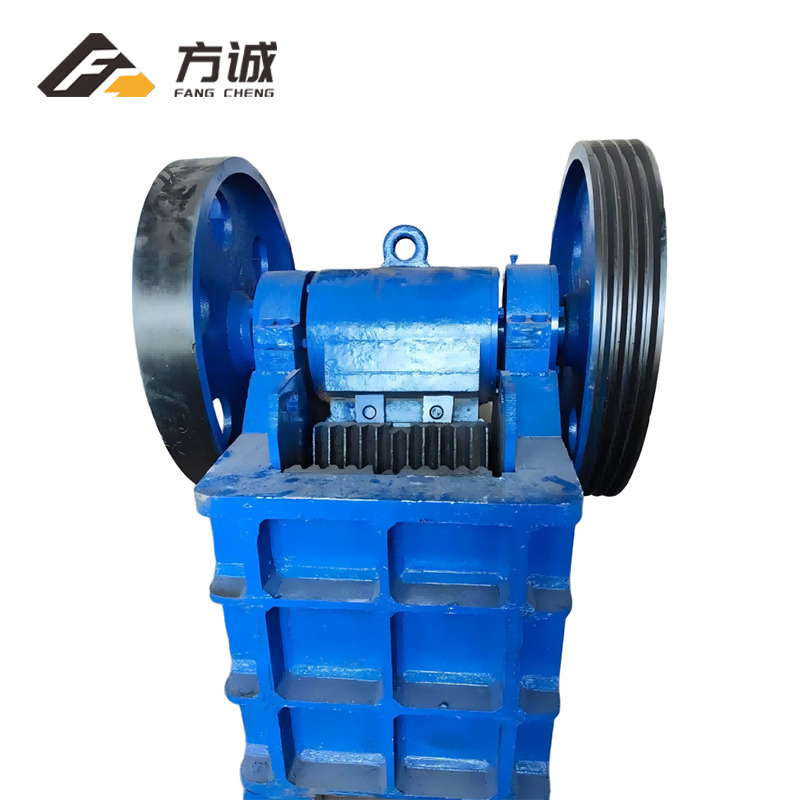

In the realm of industrial machinery, jaw crushers stand as a pivotal component in the process of reducing large rocks into smaller, more manageable pieces. These machines are indispensable in mining, construction, and recycling industries. The various types of jaw crushers cater to different needs, each designed with specific features and capabilities. Understanding the types of jaw crushers and their applications is crucial for selecting the right equipment for a given task. For more information on the specifics of jaw crushers, you can explore the detailed options available at jaw crusher.

Jaw crushers are categorized based on their design and the mechanism they use to crush materials. The primary types include the Blake crusher, the Dodge crusher, and the Universal crusher. Each type has its unique features and is suited for specific applications.

The Blake jaw crusher, invented by Eli Whitney Blake in 1858, is the most common type. It features a fixed jaw and a movable jaw pivoted at the top, creating a V-shaped cavity. This design allows for a more consistent and efficient crushing process. The Blake crusher is ideal for hard and abrasive materials, making it a staple in mining operations.

The Dodge jaw crusher differs from the Blake model by having the pivot point at the bottom. This design results in a more complex motion and allows for finer crushing. However, it is less commonly used due to its tendency to clog with sticky materials. Despite this, the Dodge crusher is suitable for laboratory and small-scale operations where finer outputs are required.

The Universal jaw crusher combines features of both the Blake and Dodge crushers. It has a movable jaw that pivots at an intermediate position, offering a balance between the two designs. This versatility makes it a popular choice for a variety of applications, from primary crushing to recycling operations.

The operation of a jaw crusher involves a series of mechanical processes that break down large rocks into smaller pieces. The primary mechanism involves the movement of the movable jaw against the fixed jaw, creating a compressive force that fractures the material. The efficiency of this process depends on several factors, including the size of the feed opening, the speed of the jaws, and the angle between the jaws.

The feed opening of a jaw crusher determines the maximum size of the input material. Larger feed openings can accommodate bigger rocks, increasing the machine's capacity. However, the size of the feed opening must be balanced with the crusher's overall dimensions to ensure efficient operation.

The speed at which the jaws move plays a crucial role in the crushing process. Faster jaw speeds result in higher throughput but can also lead to increased wear and tear. The crushing angle, or the angle between the jaws, affects the efficiency of the crushing process. A steeper angle provides more aggressive crushing but may reduce the crusher's capacity.

Jaw crushers are versatile machines used in a wide range of industries. Their primary function is to reduce the size of large rocks for further processing. In mining, they are used to crush ore before it is transported to the mill. In construction, they are used to break down concrete and other building materials for recycling. In the recycling industry, jaw crushers are used to process waste materials, turning them into reusable products.

In the mining industry, jaw crushers are used to crush ore into smaller pieces before it is processed further. This initial crushing stage is crucial for efficient extraction of minerals. Jaw crushers are favored for their ability to handle hard and abrasive materials, making them ideal for mining operations.

In construction, jaw crushers are used to break down concrete, asphalt, and other building materials. This process is essential for recycling operations, where materials are repurposed for new construction projects. Jaw crushers are valued for their ability to produce uniform-sized aggregates, which are crucial for construction applications.

The recycling industry relies on jaw crushers to process waste materials into reusable products. These machines are used to crush materials such as glass, metal, and plastic, reducing them to sizes suitable for further processing. Jaw crushers play a vital role in promoting sustainability by enabling the recycling of materials that would otherwise end up in landfills.

Jaw crushers offer several advantages, including their ability to handle a wide range of materials, their high capacity, and their efficiency in breaking down large rocks.

One of the primary advantages of jaw crushers is their ability to handle a wide range of materials, from soft to hard and abrasive. They are also capable of producing high volumes of crushed material, making them ideal for large-scale operations. Additionally, jaw crushers are known for their efficiency, as they can quickly break down large rocks into smaller pieces.

Jaw crushers are essential machines in various industries, offering the ability to efficiently break down large rocks into smaller, more manageable pieces. Understanding the different types of jaw crushers and their applications is crucial for selecting the right equipment for a given task. While jaw crushers offer numerous advantages, they also have limitations that must be considered. For those looking to explore the different types of jaw crushers and their applications, the jaw crusher options available provide a comprehensive overview of the possibilities.

1. What is the primary function of a jaw crusher?

Jaw crushers are used to reduce the size of large rocks into smaller pieces for further processing in various industries, including mining, construction, and recycling.

2. How does a Blake jaw crusher differ from a Dodge jaw crusher?

The Blake jaw crusher has a fixed jaw and a movable jaw pivoted at the top, while the Dodge jaw crusher has the pivot point at the bottom, resulting in different crushing motions and applications.

3. What industries commonly use jaw crushers?

Jaw crushers are commonly used in the mining, construction, and recycling industries for crushing various materials.

4. What are the advantages of using a jaw crusher?

Jaw crushers offer advantages such as handling a wide range of materials, high capacity, and efficiency in breaking down large rocks.

5. What are the limitations of jaw crushers?

Limitations include producing uneven particle sizes and susceptibility to wear and tear, especially with abrasive materials.

6. How can one select the right jaw crusher for a specific application?

Selection depends on factors like the material type, required output size, and the specific application needs.

7. Where can I find more information about jaw crushers?

For more details, you can visit the jaw crusher section on the FCM Mining Equipment website.