Views: 0 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

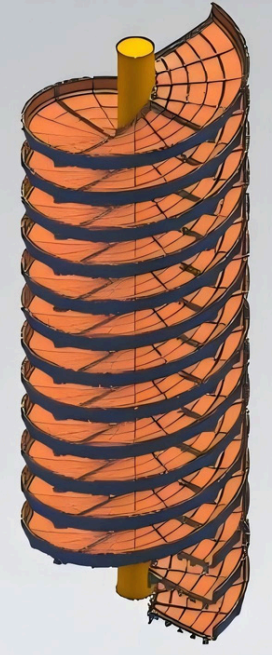

The continuous innovation of mineral processing technology has driven the evolution of gravity separation equipment. Among these advancements, the ABS spiral chute has emerged as a highly efficient and durable solution that combines polymer engineering, hydrodynamic design, and modular assembly. Through the optimization of structure, materials, and operational parameters, the ABS spiral chute has become one of the most practical and cost-effective separators used in modern mineral beneficiation plants.

Conventional spiral chutes were primarily made from fiberglass-reinforced plastic (FRP). While these units offered lightweight construction and relatively easy installation, they were limited by poor wear resistance, brittle performance, and short operational life in harsh mineral environments.

The introduction of ABS-based polymer spiral chutes marked a significant shift. By combining ABS, polyurethane, polycarbonate alloy, and nylon composites, these chutes achieved excellent mechanical strength and flexibility. They no longer deform or crack under high throughput and abrasive mineral flows, making them far more durable and stable in continuous industrial applications.

The latest ABS spiral chutes are designed through computational fluid dynamics (CFD) modeling to optimize the spiral curvature and flow path. By refining the cross-sectional curve, spiral diameter, and slope angle, engineers ensure a balanced combination of gravity, centrifugal force, and fluid resistance. This synergy enhances the stratification and separation precision of minerals ranging from 1–0.074 mm in size.

The core technology of the ABS spiral chute lies in its ability to control and distribute mineral slurry precisely. The chute’s smooth, high-performance surface minimizes turbulence and allows denser particles to move toward the inner section, while lighter gangue materials are carried outward by the slurry flow.

This multi-force separation mechanism—combining gravity, centrifugal, and fluid dynamic forces—maximizes recovery rates for fine minerals such as tungsten, tin, tantalum, niobium, zircon, monazite, and rutile.

One of the primary challenges in spiral separators is material wear. The ABS polymer and polyurethane composite construction of this chute offers superior abrasion resistance, extending service life by more than three times compared with fiberglass models. The structure also resists deformation from long-term exposure to moisture, pressure, and temperature variations.

The modular chute design is another remarkable advancement. Each unit can be disassembled into independent spiral modules, simplifying logistics and reducing on-site assembly time. With proper training, operators can complete installation within two hours, minimizing downtime and operational cost.

This modularity also allows easy maintenance—individual sections can be replaced without dismantling the entire system, improving efficiency and reducing total lifecycle cost.

The ABS spiral chute is designed for a wide range of ores, especially those with significant density differences. It is extensively used for:

Ferrous minerals: iron ore, ilmenite, and chromite

Non-ferrous minerals: tungsten, tin, and tantalum-niobium ore

Rare minerals: zircon, monazite, and rutile

Non-metallic minerals: phosphate rock and beach sand concentrates

Because of its robust adaptability, it performs effectively both in industrial mineral plants and beach sand operations where particle composition varies widely.

Fine particle recovery has long been a bottleneck in gravity separation. Through precise adjustment of spiral slope and slurry density, the ABS spiral chute can achieve accurate stratification even for ultrafine particles. This improvement significantly raises recovery efficiency and concentrate grade, leading to higher profitability in large-scale beneficiation plants.

In actual mineral processing plants, the ABS spiral chute is often used in combination with other separation equipment, such as shaking tables, centrifugal concentrators, and magnetic separators. When integrated in a roughing–cleaning–scavenging circuit, it performs an efficient preliminary sorting step, which reduces load on subsequent refining units and enhances overall plant throughput.

In a titanium ore project in Southeast Asia, the application of the ABS spiral chute increased concentrate recovery by 15% compared with fiberglass spirals. The modular system also reduced transportation cost and assembly time by over 40%, highlighting its value in international operations where compact shipping and rapid deployment are critical.

As a purely gravity-driven separator, the ABS spiral chute operates without the need for external power or mechanical drives. This simplicity not only minimizes operational energy costs but also reduces maintenance frequency, aligning with modern sustainability standards in mining.

The use of high-strength polymer materials makes the chute environmentally responsible. ABS and polyurethane are recyclable, and their extended lifespan minimizes waste production. This aligns with the principles of green mineral processing and sustainable development in modern mining industries.

The ongoing development of polymer materials and computational modeling will further refine spiral chute performance. Researchers are exploring nanocomposite coatings and smart monitoring systems that can detect flow irregularities in real time. These innovations will push ABS spiral chutes toward higher automation, precision, and sustainability, reinforcing their central role in gravity separation technology.

Jiangxi Fangcheng Mining Equipment Manufacturing Co., Ltd. is a professional enterprise dedicated to the R&D, production, and sales of mineral processing machinery. The company’s product range covers feeding, crushing, grinding, screening, flotation, gravity, magnetic, and drying equipment, serving global customers with customized solutions.

Its ABS spiral chute represents the company’s commitment to innovation, combining engineering excellence with sustainable materials to deliver durable, high-efficiency mineral separation equipment trusted worldwide.

Q1: What makes the ABS spiral chute different from fiberglass models?

A1: The ABS spiral chute uses advanced polymer materials with superior wear resistance, longer service life, and improved separation accuracy compared with fiberglass models.

Q2: Can the chute handle both fine and coarse particles?

A2: Yes. It is optimized for separating minerals between 1 mm and 0.074 mm, allowing effective classification of both coarse and fine fractions.

Q3: Is the ABS spiral chute suitable for mobile or field installations?

A3: Absolutely. Its modular design allows easy on-site assembly, making it ideal for remote mining sites or pilot-scale operations.

Q4: Does it require power or mechanical movement?

A4: No external power source is needed—the separation process relies entirely on gravity and slurry flow, making it energy-efficient and eco-friendly.

Q5: What is the typical lifespan of an ABS spiral chute?

A5: Depending on operational conditions, its service life can exceed 5 years, significantly outlasting traditional fiberglass spiral chutes.